Home

Product

Service

About Us

Contact

Home

Product

Service

About Us

Contact

Designed by: WebStation

Computer Centre

Designed by: WebStation

Computer Centre

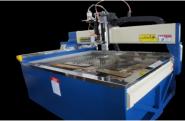

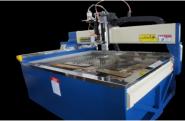

Waterjet cutting technology is one of the fastest growing major machine tool

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation. There are

processes in the world due to its versatility and ease of operation. There are virtually no limits to what waterjets can cut, which is why companies of all kinds

virtually no limits to what waterjets can cut, which is why companies of all kinds and sizes are realizing greater efficiency and productivity by implementing UHP

and sizes are realizing greater efficiency and productivity by implementing UHP waterjets in their operations.

waterjets in their operations. Since Flow first invented abrasive waterjet technology in the early 1980s, the

Since Flow first invented abrasive waterjet technology in the early 1980s, the technology has evolved rapidly. Decades of research have led to the

technology has evolved rapidly. Decades of research have led to the development of waterjets that do more and cost less. Here’s how Flow waterjets

development of waterjets that do more and cost less. Here’s how Flow waterjets can benefit your business:

can benefit your business:

Why choose water jet

Why choose water jet

Aerospace:

Our waterjet machine can cut any known materials including composites, laminates,

Aerospace:

Our waterjet machine can cut any known materials including composites, laminates, plastics, rubbers, castings, forging, aluminum, stainless steel, hardened or tool

plastics, rubbers, castings, forging, aluminum, stainless steel, hardened or tool steel, exotic alloys, heat sensitive materials, as well as synthetics that may release

steel, exotic alloys, heat sensitive materials, as well as synthetics that may release harmful vapors when cut using other methods. Popular aerospace applications are

harmful vapors when cut using other methods. Popular aerospace applications are the cutting of brackets, mounts, tooling, instrument panels, various mechanisms,

the cutting of brackets, mounts, tooling, instrument panels, various mechanisms, consoles.

consoles.

Manufacturing:

Manufacturing: We accurately produce parts for products that are sold on the retail market, as well

We accurately produce parts for products that are sold on the retail market, as well as many of the parts used to make the machines on assembly lines.

as many of the parts used to make the machines on assembly lines. Automotive & transportation:

Automotive & transportation: Prototyping and production parts for automobiles, and the tooling for making

Prototyping and production parts for automobiles, and the tooling for making automobiles, trains, ships, motorcycles.

automobiles, trains, ships, motorcycles.

Model making/rapid prototyping:

Fast turn around of single or limited quantity production of nearly any

Model making/rapid prototyping:

Fast turn around of single or limited quantity production of nearly any material.

material. Artists:

Stained glass, marble and stone, metal sculpture, jewelry, and more.

Artists:

Stained glass, marble and stone, metal sculpture, jewelry, and more.

1) Unmatched Versatility

1) Unmatched Versatility Flow waterjets enable you to cut a variety of applications with ease.

Flow waterjets enable you to cut a variety of applications with ease. Whatever the shape, dimensions, or material, our easy-to-use

Whatever the shape, dimensions, or material, our easy-to-use software makes the job easy.

software makes the job easy.  2) Reduced Material and Production Costs

2) Reduced Material and Production Costs Flow waterjets require minimal fixturing and tooling so you can save

Flow waterjets require minimal fixturing and tooling so you can save valuable time on your shop floor. Waterjets cut accurate, clean

valuable time on your shop floor. Waterjets cut accurate, clean edges that allow for tight nesting and reduced scrap — saving you

edges that allow for tight nesting and reduced scrap — saving you money through greater material utilization.

money through greater material utilization.

Home

Product

Service

About Us

Contact

Home

Product

Service

About Us

Contact

Designed by: WebStation

Computer Centre

Designed by: WebStation

Computer Centre

Waterjet cutting technology is one of the fastest growing major machine tool

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world due to its versatility and ease of operation. There are

processes in the world due to its versatility and ease of operation. There are virtually no limits to what waterjets can cut, which is why companies of all kinds

virtually no limits to what waterjets can cut, which is why companies of all kinds and sizes are realizing greater efficiency and productivity by implementing UHP

and sizes are realizing greater efficiency and productivity by implementing UHP waterjets in their operations.

waterjets in their operations. Since Flow first invented abrasive waterjet technology in the early 1980s, the

Since Flow first invented abrasive waterjet technology in the early 1980s, the technology has evolved rapidly. Decades of research have led to the

technology has evolved rapidly. Decades of research have led to the development of waterjets that do more and cost less. Here’s how Flow waterjets

development of waterjets that do more and cost less. Here’s how Flow waterjets can benefit your business:

can benefit your business:

Why choose water jet

Why choose water jet

Aerospace:

Our waterjet machine can cut any known materials including composites, laminates,

Aerospace:

Our waterjet machine can cut any known materials including composites, laminates, plastics, rubbers, castings, forging, aluminum, stainless steel, hardened or tool

plastics, rubbers, castings, forging, aluminum, stainless steel, hardened or tool steel, exotic alloys, heat sensitive materials, as well as synthetics that may release

steel, exotic alloys, heat sensitive materials, as well as synthetics that may release harmful vapors when cut using other methods. Popular aerospace applications are

harmful vapors when cut using other methods. Popular aerospace applications are the cutting of brackets, mounts, tooling, instrument panels, various mechanisms,

the cutting of brackets, mounts, tooling, instrument panels, various mechanisms, consoles.

consoles.

Manufacturing:

Manufacturing: We accurately produce parts for products that are sold on the retail market, as well

We accurately produce parts for products that are sold on the retail market, as well as many of the parts used to make the machines on assembly lines.

as many of the parts used to make the machines on assembly lines. Automotive & transportation:

Automotive & transportation: Prototyping and production parts for automobiles, and the tooling for making

Prototyping and production parts for automobiles, and the tooling for making automobiles, trains, ships, motorcycles.

automobiles, trains, ships, motorcycles.

Model making/rapid prototyping:

Fast turn around of single or limited quantity production of nearly any

Model making/rapid prototyping:

Fast turn around of single or limited quantity production of nearly any material.

material. Artists:

Stained glass, marble and stone, metal sculpture, jewelry, and more.

Artists:

Stained glass, marble and stone, metal sculpture, jewelry, and more.

1) Unmatched Versatility

1) Unmatched Versatility Flow waterjets enable you to cut a variety of applications with ease.

Flow waterjets enable you to cut a variety of applications with ease. Whatever the shape, dimensions, or material, our easy-to-use

Whatever the shape, dimensions, or material, our easy-to-use software makes the job easy.

software makes the job easy.  2) Reduced Material and Production Costs

2) Reduced Material and Production Costs Flow waterjets require minimal fixturing and tooling so you can save

Flow waterjets require minimal fixturing and tooling so you can save valuable time on your shop floor. Waterjets cut accurate, clean

valuable time on your shop floor. Waterjets cut accurate, clean edges that allow for tight nesting and reduced scrap — saving you

edges that allow for tight nesting and reduced scrap — saving you money through greater material utilization.

money through greater material utilization.